We manufactured high quality hydraulic clamps for secure clamping and safer operations.

Lot of quality testing are done before supplied to the customers.

There are two different clamps available for suit your high press lines and injection molding

TA Type

This type dis clamps are manufactured to fit into the ‘T’ slot of the bed for secure positioning.

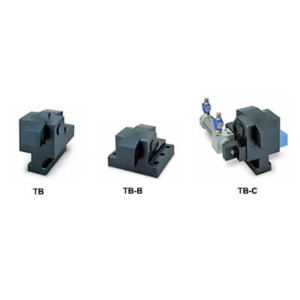

TB Type

This type of clamps are mainly used injection molding applications

‘u’ cuts are no need.

Traditional Clamps

- Manual operation

- Lesser productivity

- While changing the die/ mold, it takes long time for tighten.

- The tightening force will be the clamping force different by different operations is same

- Injury may happen while lightening

- No alarm notification while screws are losing.

Hydraulic clamps

- Automation

- Increased productivity

- Few seconds for clamping

- The clamping force is same

- Increased safety

- With alarm device the machine will stop immediately.

Specify ‘T’ slot dimensions (A,B,C,D) and tool height (H) when ordering.

Clamps with dimension greater than max. h+D are available (when required)

Custom strokes are available on request.